- Product Details

Keywords

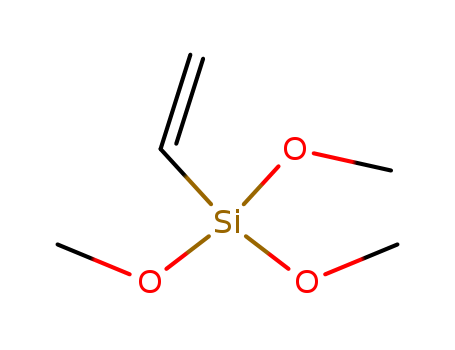

- Vinyltrimethoxysilane

- Vinyltrimethoxysilane price

- 2768-02-7

Quick Details

- ProName: Vinyltrimethoxysilane

- CasNo: 2768-02-7

- Molecular Formula: C5H12O3Si

- Appearance: Colorless transparent liquid

- Application: cross-linking agent

- PackAge: 1000Kg IBC; 190-200KG iron or polyethy...

- ProductionCapacity: 1000 Metric Ton/Year

- Purity: Min 98.0%

- Storage: In the cool, dry place

- Transportation: ocean shipping/air transport

- LimitNum: 10 Kilogram

Superiority

—————————————————————&md

Details

————————————————————————————————

Chemical Name Vinyltrimethoxysilane

Formula C5H12O3Si

Molecular Weight 148.2

Color and Appearance Colorless transparent liquid

Density 25/25℃ 0.960-0.970

Boiling Point 122【760mmHg】

Refractive Index 1.3905 +/- 0.0005【25℃】

Flash Point 28

CAS No. 2768-02-7

Purity Min 98.0%

———————————————————————————————————

【Trademark in abroad】

| Wacker | Dow Corning | Shin-Etsu | Momentive | EVONIK | Chisso |

| GENIOSIL Xl 10 | Z-6300 | KBM-1003 | A-171 | Dynasylan VTEO | SILA-AceS-220 |

【Packaging & Delivery】

| Packaging | Detail | Packaging | Detail |

| 1000Kg IBC (Intermediate Bulk Container) Length: 1200 mm Width: 1000 mm Height: 1160 mm Pallet: Steel Outlet valve: Integrated butterfly valve DN 50 Screwable ball valve DN 50 |  | 190-200 kg polyethylene barrels Diameter: 580 mm Height: 900 mm |

| 190-200 kg iron drums Diameter: 571 mm Height: 880-950 mm |  | 10Kg Polyethylene Barrels |

【Scale of Production】

| Item | Detail |

| Min. Order | 10 Kilogram |

| Production Capacity | 1000 Ton/Year |

| Inventory | In stock |

【Applications of Vinyltrimethoxysilane】

Polymer Modification

Vinyltrimethoxysilane is used to modify polyethylene and other polymers by grafting its vinyl group to the polymer backbone using a radical initiator, such as peroxide. This provides a polymer with pendant trimethoxysilyl groups that may be used as moisture-activated crosslinking sites via hydrolysis of the alkoxy groups followed by condensation of the resulting silanols.

Crosslinking of Silane-Grafted Polymers

The reaction of Silane-grafted polyethylene to form a crosslinked or vulcanized polyethylene uses water to form the crosslinks. This technology is widely used around the world for commercial applications in wire and cable insulation, tubing, and other similar uses.

【Benefits of Crosslinking】

Higher maximum use temperature

Reduced deformation under load (creep)

Improved chemical resistance

Superior environmental stress crack resistance

Increased abrasion resistance

Improved impact strength

【Advantages of Silane Crosslinking over Radiation or Peroxide Crosslinking】

Low capital investment

Low operating (energy) costs

Higher productivity

Processing versatility

Thick, thin, or variable thicknesses possible

【Other Vinyl Coupling Agent】

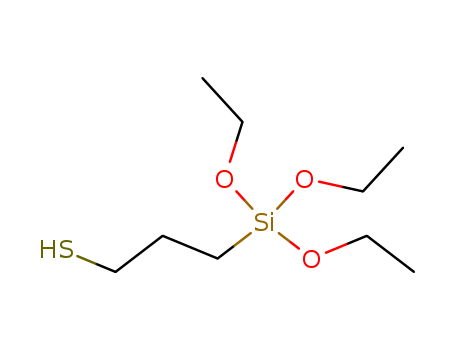

Silane coupling agent A-150 Silane Coupling Agent A-151 Silane Coupling Agent A-172

(75-94-5) (78-08-0) (1067-53-4)