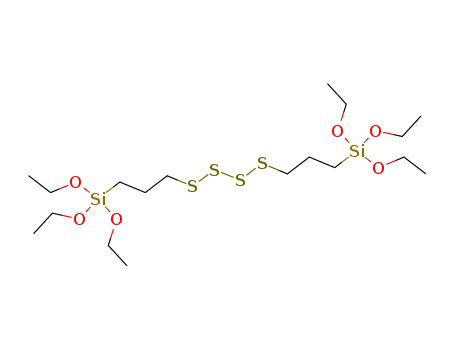

Bis[3-(triethoxysilyl)propyl]tetrasulfide CAS NO.40372-72-3

- Min.Order: 1 Gram

- Payment Terms:

- Product Details

Keywords

- 40372-72-3

- Bis[3-(triethoxysilyl)propyl]tetrasulfide

- Bis[3-(triethoxysilyl)propyl]tetrasulfide price

Quick Details

- ProName: Bis[3-(triethoxysilyl)propyl]tetrasulf...

- CasNo: 40372-72-3

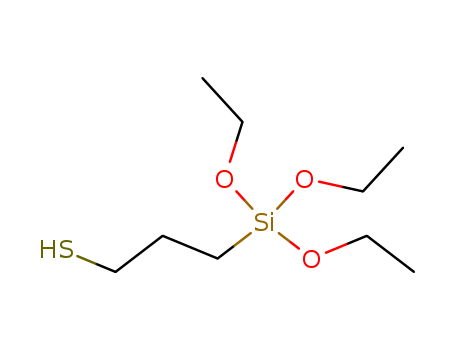

- Molecular Formula: C18H42O6S4Si2

- Appearance: Yellowish liquid

- Application: used in rubber compounds

- PackAge: 1000Kg IBC; 190-200KG iron or polyethy...

- ProductionCapacity: Metric Ton/Day

- Purity: 95% min

- Storage: In the cool, dry place

- Transportation: ocean shipping/air transport

- LimitNum: 1 Gram

Superiority

KBM-846

Details

Assay Appearance Volatiles components Average chain length (%) Total Sulfur (standard value)(%) 95% min Yellowish liquid (%) <= 4.0 3.75 +/- 0.15 22.7 +/- 0.8

【Trademark in abroad】Our Brand Dow Corning Shin-Etsu Momentive EVONIK China WD-40 Z-6940 A-1289 Si 69 Silane coupler KH-858

【Packing of (CAS No. 40372-72-3)】

(1) 1000Kg IBC (Intermediate Bulk Container:1200mm*1000mm*1160mm)

(2) 190-200KG polyethylene drum (diameter 580mm; height 900mm) or iron drum (diameter 571mm; height 880-950mm)

(3) 10Kg polyethylene drum or with smaller packing

(The packing picture are listed as in order).jpg)

【Transportation & Payment】Payment Terms Escrow Service Transportation Delivery Time T/T; L/C; D/P Support Ocean shipping/air transport 3-7Days

【Sample Service】Free samples Quantity Transportation Fees Allow < 100g At your own expense

【Application of Bis[3-(triethoxysilyl)propyl]tetrasulfide (CAS No. 40372-72-3)】

Dosage

Suggested dosage per 100 parts of filler:

For silica-------------------3~13 parts

For clay and talc----------0.5~1.0 parts

When used in rubber compounds, Silane coupler KH-858(CAS No. 40372-72-3) produces these effects:

(1) Coupling agent for non-black pigments.

(2) Cure equilibrium for reversion resistance.

(3) Curing agent for good heat aging.

? Coupling Agent - With as little as 0.5 to 1.0 phr with clay fillers and 1.0 to 4.0 phr for silica pigments, Silane coupler KH-858 couples the non-black pigment and elastomers resulting in increases in modulus and increase in abrasion resistance.

? Cure Equilibrium - Silane coupler KH-858 has four sulfur atoms positioned in the center.

At cure temperatures, these participate with sulfur in producing polysulfidic crosslinks. The Silane coupler KH-858 replaces crosslinks broken during cure, resulting in reversion resistant, and with proper compounding, reversion free compounds. This is known as equilibrium cure. The dynamic flex characteristics, E.G., heat generation and crack growth, are dramatically improved.

? Curing Agent - Removing all sulfur from the compound for NR, SBR, NBR and replacing it with Silane coupler KH-858 and certain thiuram accelerators, produces compounds with excellent heat aging characteristics in addition to the coupling effects.

Silane coupler KH-858 is a silane coupling agent that has crosslinking and accelerator activity in rubber compounds.

【Areas of rubber industry where them would be beneficial】

Footwear

- Abrasion resistance

- Cutting and chunking resistance

- Flex life improvement

Rolls

- Abrasion resistance

- Aging resistance

- Processing

- Set reduction (better load bearing)

- Reduced water swell

- Lower hysteresis

Mechanical Molded Goods

- Increased modulus

- Better heat aging

- Compression set reduction

- Dynamic property improvement

- Reduced swell to polar liquids

- Filler substitution (non-black for black)

Hose

- Improved abrasion on cover

- Better heat aging

- Increased modulus

- Lower compression set

- Improved adhesion to reinforcing elements

Solid Tires

- Improved abrasion

- Lower hysteresis

- Higher modulus

- Improved processing

- Possibly better adhesion

Tires

- Treads for abrasion, hot tear

- Carcass for adhesion and/or filler substitution

- Breaker (belt) stocks for adhesion

Belts

Flat Belts

- Increased abrasion

- Improved reversion resistance

- Reduced cost with clay substitution for black

- Improved cord adhesion

- Increased flex life and modulus

V Belts

- Increased modulus

- Improved abrasion

- Longer flex life

- Improved adhesion to reinforcing elements

WD Silicone Co., LtdTel:+86-27-87204219, +86-27-87215023 Fax:+86-27-87214371 Email:sale@wdsilicone.cn

Address:2402, HuiGu Space-time Building, 8 Forest Road, East Lake Hi-Tech Development Zone,430070